| Appearance | 无色液体 | UN | UN 2290 6.1/PG 3 |

| HS | 2929109000 | DG Class | 6.1 |

| Synonyms | IPDI | ||

Customer Service

Customer Service

-

Email:contact@synverta.org

Email:contact@synverta.org

-

Tel:+85295802879

Tel:+85295802879

-

landline:

landline:

- 纯度99.8%

Overview

Product Information

Excellent resistance to yellowing and ultraviolet (UV) degradation

Superior gloss retention and weatherability

Provides high transparency, outstanding mechanical strength, and chemical resistance

Low volatility and low toxicity, offering a more environmentally friendly alternative to aromatic diisocyanates

Specification

Product Application

🧪 1. Coatings

1. Polyurethane Coatings (PU Coatings)

IPDI is a key raw material for the preparation of aliphatic polyurethane prepolymers or NCO-terminated resins (such as IPDI trimer or IPDI biuret).

Features:

Excellent UV and yellowing resistance (superior to TDI and MDI)

Outstanding gloss and color retention

High durability and weatherability

Typical applications:Automotive, aircraft, and marine topcoats

Wood varnishes, plastic coatings

High-performance anti-corrosion coatings for outdoor exposure

🧴 2. Adhesives and Sealants

IPDI reacts with polyether or polyester polyols to form flexible and weather-resistant polyurethane adhesives.

Advantages:

Low monomer content (low VOC)

Excellent heat and hydrolysis resistance

Applications:Construction sealants, automotive assembly adhesives

Electronic encapsulants

Laminating adhesives for flexible packaging

🧰 3. Elastomers

Used in the production of aliphatic polyurethane elastomers (PU Elastomers) with:

High tensile and tear strength

Excellent abrasion resistance and UV stability

Applications:Transparent optical components (e.g., lenses, clear tubing)

Medical devices, sports equipment, precision mechanical parts

💧 4. Waterborne Polyurethane Dispersions (PUD)

IPDI is one of the main diisocyanates used for producing high-performance waterborne polyurethanes (WPU).

It plays a key role in achieving high transparency, flexibility, and non-yellowing appearance.

Applications:

Leather and textile coatings

Eco-friendly wood and industrial coatings

Waterborne adhesive systems

🔬 5. Specialty Applications

1. UV-Curable Polyurethane Acrylates (PUA)

IPDI is used to synthesize urethane acrylate oligomers or monomers with excellent flexibility and scratch resistance.

Applications:

UV-curable inks, electronic coatings, optical materials

2. Medical and Optical Polymers

Due to its low toxicity and chemical stability, IPDI-based polymers are used in:

Medical coatings and biocompatible materials

Transparent optical resins

⚗️ 6. Comparison with Other Diisocyanates

| Property | IPDI | HDI (Hexamethylene Diisocyanate) | TDI (Toluene Diisocyanate) | MDI (Diphenylmethane Diisocyanate) |

|---|---|---|---|---|

| Type | Aliphatic (cycloaliphatic) | Aliphatic (linear) | Aromatic | Aromatic |

| Yellowing Resistance | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ |

| Weather Resistance | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ |

| Hardness | Medium–High | Medium | High | High |

| Typical Uses | High-end coatings, WPU | Coatings, sealants | Foams | Elastomers, foams |

Properties

Summary

| Formula | C12H18N2O2 | Molecular Mass | 222.28 |

| EINECS | 223-861-6 | Storage conditions | Dry |

| Stability | stable | ||

| IUPAC | |||

| LEAD TIME | 1 week | ||

Attribute classification

| Matter Classification | |

| Category |

Chemical and Physical Properties

| Melting Point | -60°C | Density | 1.049 g/mL at 25 °C(lit.) |

| Boiling Point | 158-159 °C15 mm Hg(lit.) | Flash Point | >230 °F |

| Appearance | 无色液体 | Acidity And Basicity |

Other information

| HS Code | 2929109000 | UN | UN 2290 6.1/PG 3 |

| DG-Class | 6.1 | Upstream Raw Materials | |

| Downstream product | |||

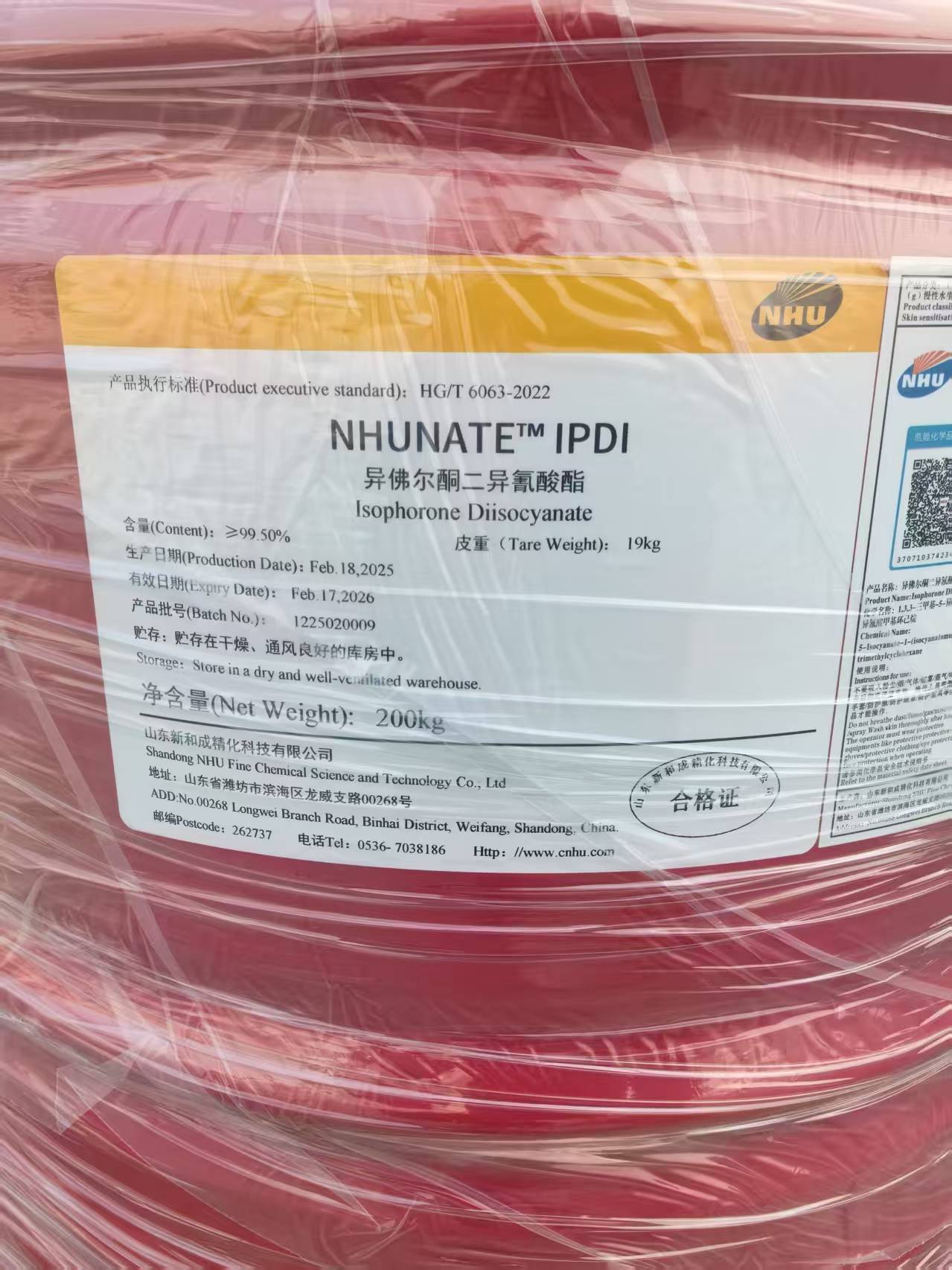

Isophorone diisocyanate

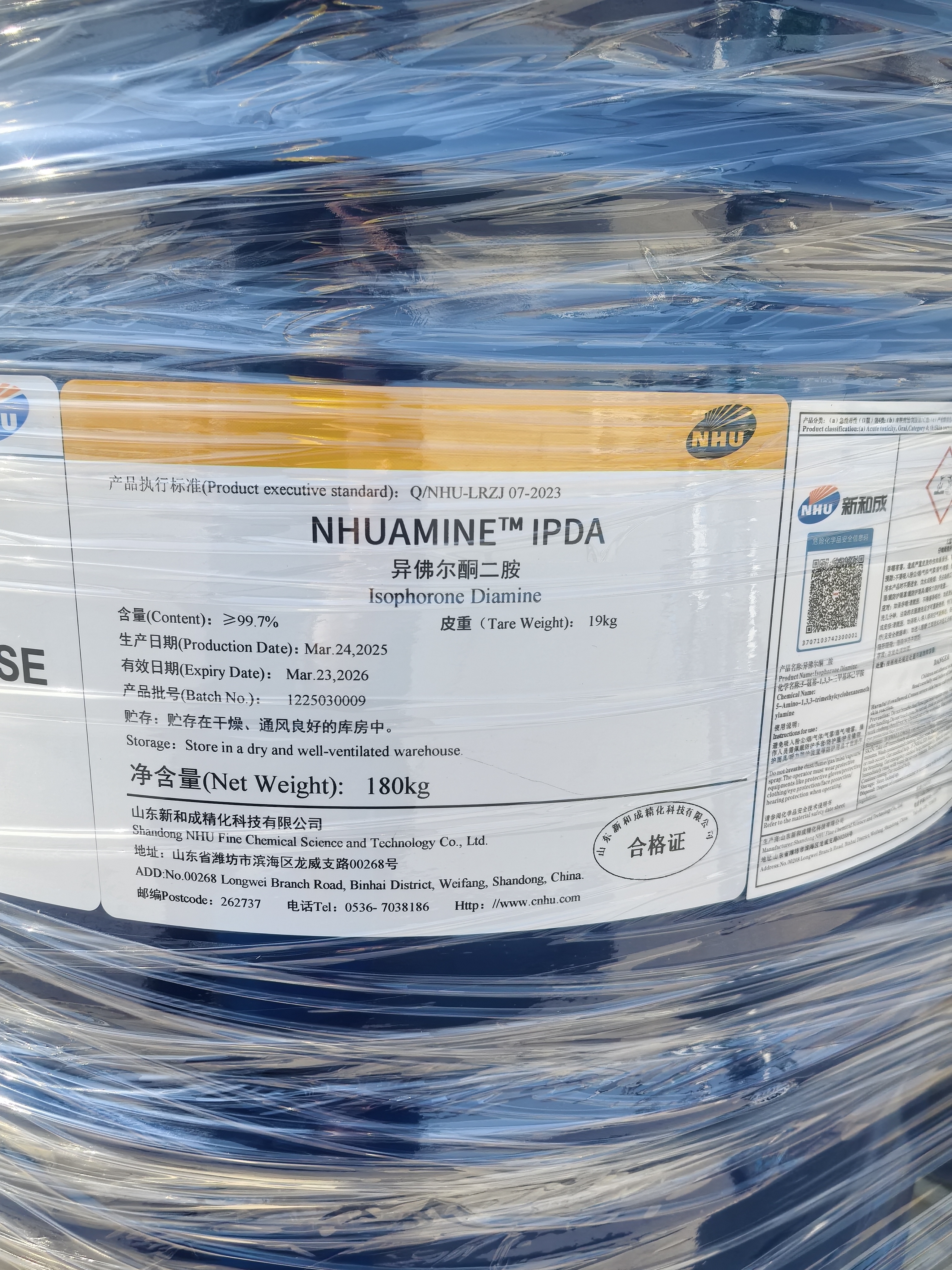

purity 99.7%

Quantity

kg

Address

China